Why Vacuum Brazing?

Vacuum brazing is a highly effective method for joining diamond tools and is preferred over traditional soldering methods for several reasons. First, vacuum brazing produces high-strength joints that are difficult to wet by materials such as diamonds, PCD, and PCBN. This results in a more secure bond between the diamond and the tool body, leading to increased tool life and durability.

Second, the process of vacuum brazing is very clean and environmentally friendly, as it does not require the use of fluxes or other chemicals. This is particularly important for diamond tools, as the presence of impurities in the soldering process can negatively impact their performance.

Third, the constant and even distribution of temperature across all components during vacuum brazing helps to avoid residual stresses in the components that can result from heating and subsequent cooling. This helps to retain the thermal and mechanical properties of the diamond tool, and can even improve them in some cases.

Finally, vacuum brazing allows for multiple components with multiple brazing points to be joined simultaneously in one brazing process, as all workpieces are exposed to the same brazing temperature due to radiant heat. This increases efficiency and reduces production time, making it a cost-effective option for diamond tool manufacturers.

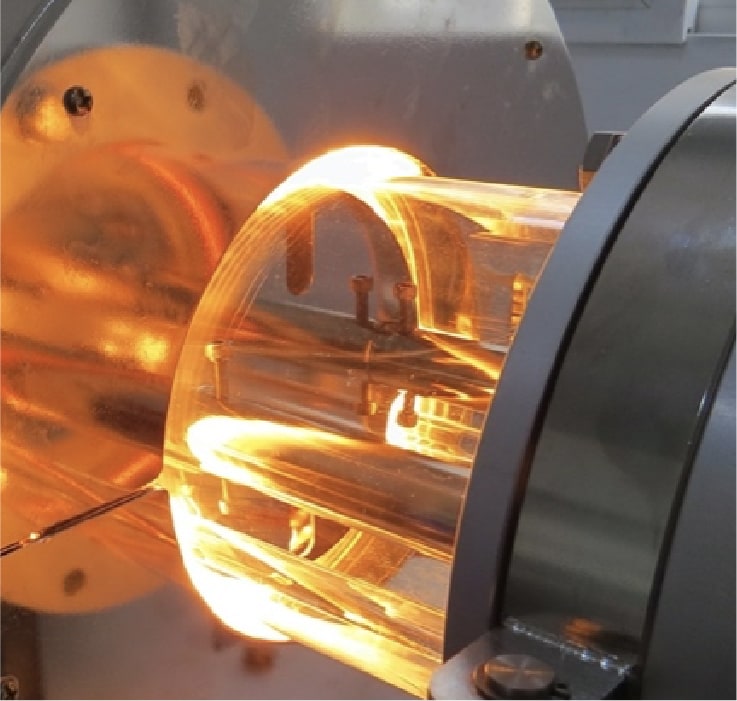

Experience the excellence in vacuum brazing with PINPOWER's advanced PP series. Our machines are meticulously engineered to meet the diverse demands of modern industries, offering unparalleled performance and reliability. The PP series includes three models: PP-S, PP-SPLUS, and PP-H, each designed to provide optimal brazing solutions.

Models Overview

| Function/Product No. | PP-S | PP-SPLUS | PP-H |

|---|---|---|---|

| Vacuum Chamber Diameter (mm) | 150 | 150 | 184 |

| Human Machine Interface (HMI) | 9" | 10" | 10" |

| Resolution | 800 x 480 | 1,280 x 800 | 1,280 x 800 |

| Energy Management | - | ◎ | ◎ |

| Remote Access and Data Collection* | - | ◎ | ◎ |

| Temperature Discrepancy Alert | ◎ | ◎ | ◎ |

| Annual Maintenance Reminder | ◎ | ◎ | ◎ |

| Cooling System Monitoring | - | ◎ | ◎ |

* Optional

Technical Specifications

| Power | 380 V, 3 Phases, 60 A, 5 wires, 40 KVA |

|---|---|

| Cooling Water | 50 L/min, 19,200 BTU/hr |

| Control System | PLC control integrated with 20 programming recipes |

| Vacuum Chamber | Ø 184 mm (PP-H) |

| Heating System | 24 kW, heating rate of 800 ℃/min, accuracy ± 3 ℃ maximum operating temperature 950 ℃ |

| Vacuum System | High vacuum pump 1,100 L/sec ultimate vacuum pressure < 9 x 10⁻⁶ torr |