なぜ真空ろう付けなのか?

真空ろう付けは、ダイヤモンド工具の接合に非常に有効な方法であり、いくつかの理由から従来のはんだ付け方法よりも好まれます。まず真空ろう付けでは、ダイヤモンド、PCD、PCBNなどの素材が濡れにくい高強度の接合部を形成します。その結果、ダイヤモンドと工具本体がより確実に接合され、工具の寿命と耐久性の向上につながります。

第二に、真空ろう付けのプロセスは、フラックスやその他の化学物質を使用する必要が無いため、非常にクリーンで環境に優しいという事です。特にダイヤモンド工具は、はんだ付けの際に不純物があると、その性能に悪影響を及ぼすため、この点は重要です。

第三に、真空ろう付けの際、全ての部品に一定の均一な温度分布が生じる為、加熱とその後の冷却によって生じる部品の残留応力を回避することが出来ます。これにより、ダイヤモンド工具の熱的・機械的特性を維持することができ、場合によって改善することも可能です。

最後に、真空ろう付けでは、輻射熱によりすべてのワークが同じろう付け温度にさらされるため、一度のろう付け工程で複数のろう付け箇所を持つ複数の部品を同時に接合する事が可能です。そのため、効率が上がり、生産時間が短縮されるため、ダイヤモンド工具メーカーにとって費用対効果の高い選択肢となります。

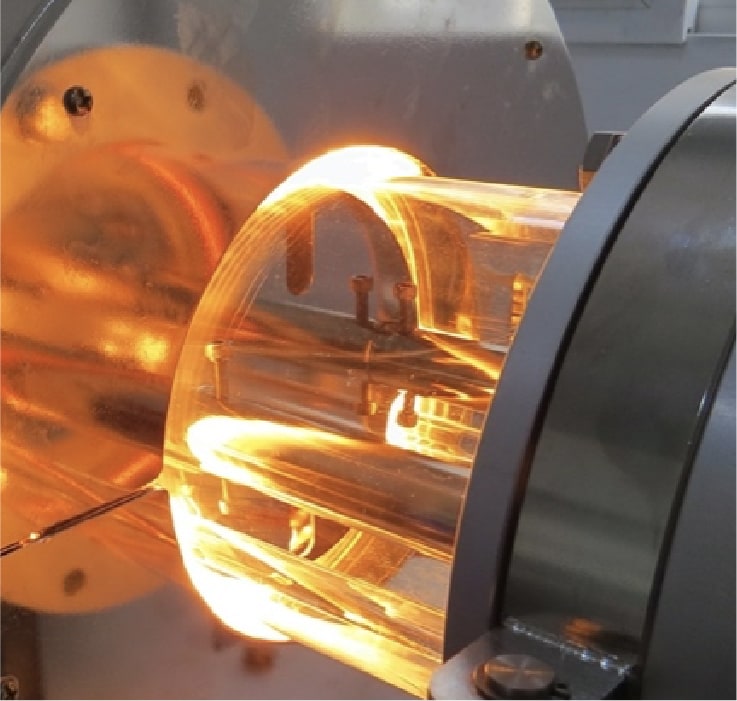

PINPOWERの先進的なPPシリーズで、真空ろう付けの優れた性能を体験してください。当社の機械は現在産業の多様な要求に応える様慎重に設計されており、比類のないパフォーマンスと信頼性を提供します。PPシリーズにはPP-S、PP-SPLUS、PP-Hの3つのモデルが含まれており、それぞれが最適なろう付けソリューションを提供する様に設計されています。

モデル概要

| 機能/製品番号 | PP-S | PP-SPLUS | PP-H |

|---|---|---|---|

| 真空チャンバー直径 (mm) | 150 | 150 | 184 |

| HMI | 9" | 10" | 10" |

| 解像度 | 800 x 480 | 1,280 x 800 | 1,280 x 800 |

| エネルギー管理 | - | ◎ | ◎ |

| リモートアクセスとデータ収集* | - | ◎ | ◎ |

| 温度不一致アラート | ◎ | ◎ | ◎ |

| 年次メンテナンスリマインダー | ◎ | ◎ | ◎ |

| 冷却システムのモニタリング | - | ◎ | ◎ |

* オプション

技術仕様

| 電源 | 380 V, 3相, 60 A, 5線, 40 KVA |

|---|---|

| 冷却水 | 50 L/min, 19,200 BTU/hr |

| 制御システム | 20のプログラミングレシピを統合したPLC制御 |

| 真空チャンバー | Ø 184 mm (PP-H) |

| 加熱システム | 24 kW, 加熱速度 800 ℃/min, 精度 ± 3 ℃ 最大運転温度 950 ℃ |

| 真空システム | 高真空ポンプ 1,100 L/sec、 最終圧力 < 9 x 10⁻⁶ torr |